Manar thrives on tackling the toughest challenges in thermoplastic injection molding. We offer smarter, more efficient processes that add real value, improved performance and affordability.

Backed by a team of dedicated employee-owners, we understand the critical role a reliable partnership plays in your success. We serve as a guiding light, helping businesses steer clear of disruptions, delays, quality concerns and scalability challenges. We’re committed to continuous improvement, flexibility and innovation, we leverage cutting-edge technology to ensure your operations stay on course. With Manar by your side, your products — and your business — are always on the path to success.

Complex Geomotries And Engineering-Grade Materials

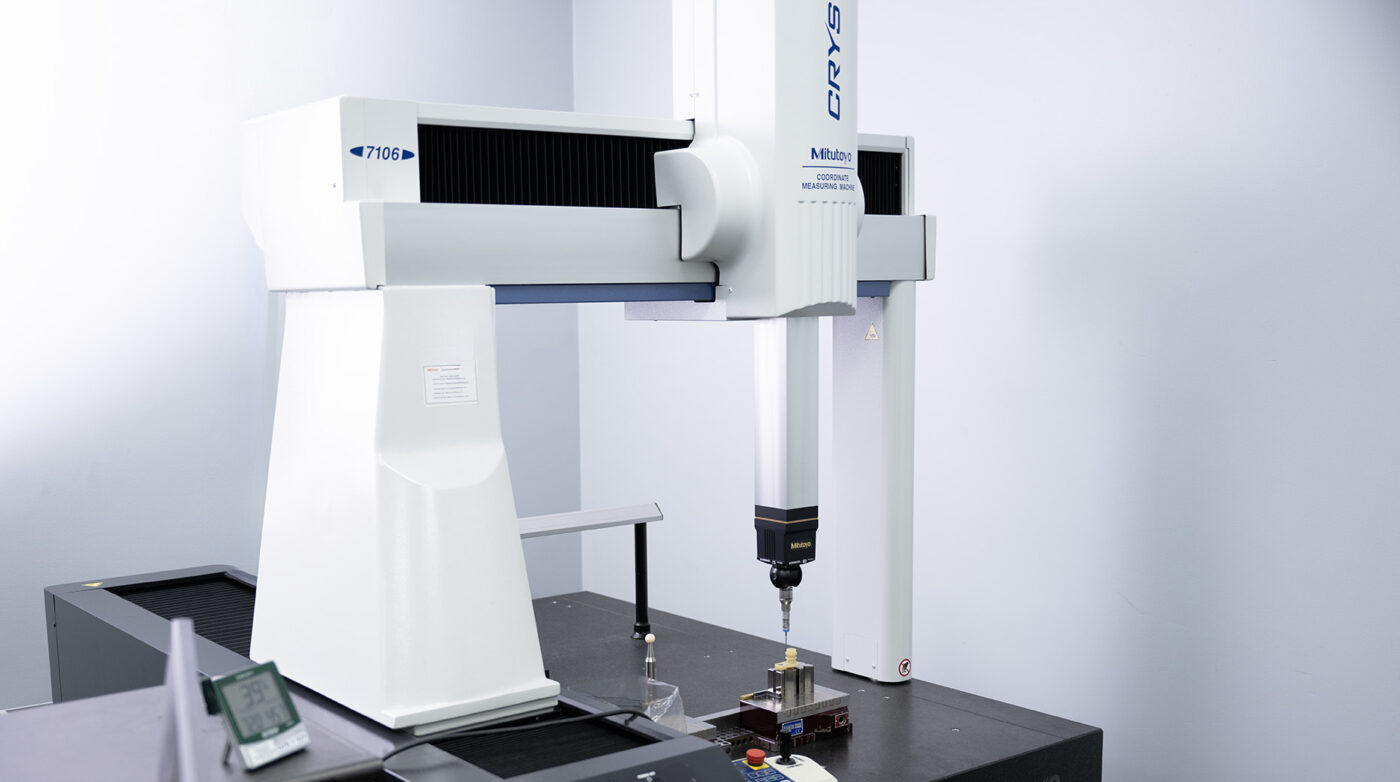

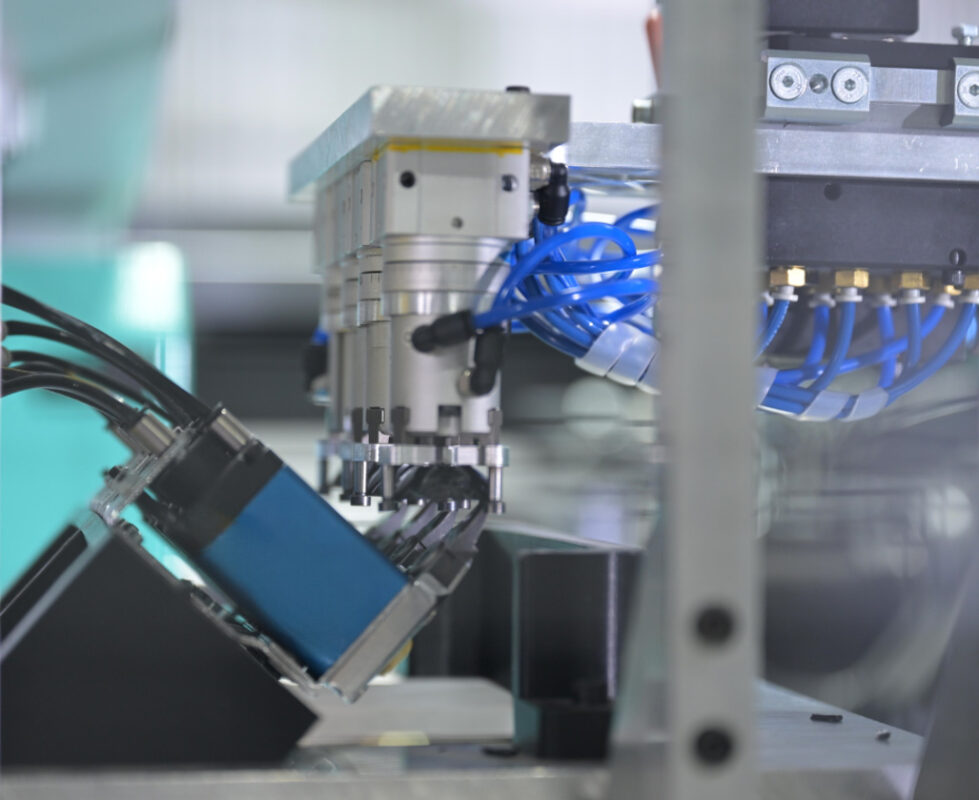

We offer a comprehensive suite of manufacturing capabilities, ensuring that we can handle every step of the process from concept to completion. Our expertise allows us to work with complex and engineering-grade materials, making us a trusted partner across industries.

Consumers increasingly value products that are made in the USA. With Manar, you can offer:

At Manar, we’re committed to being more than just a supplier, we’re your long-term partner. With a focus on innovation, efficiency and quality, we guide your project every step of the way to ensure success. Our capabilities are designed to meet the evolving needs of today’s markets, helping you navigate complex challenges with confidence.

Manar is ready to help you turn your ideas into reality. Let us show you the smarter way forward — your guiding light in thermoplastic injection molding.